AutoCAST is a software program for casting methods design, simulation and optimization developed by IIT Bombay. The listener or viewer uses special client application software on a computer or media player, known as a podcatcher, which accesses this web feed, checks it for updates, and downloads any new files in. SOLIDCast - Casting Simulation Software. Casting Simulation Software. SOLIDCast is being used by over 500 companies worldwide. No other Casting Simulation software offers power, ease of. Use and accuracy like SOLIDCast. See how your casting will solidify before you make. Expensive molds or patterns, dies and costly mistakes.

Infrastructure

World class modern infra to produce Global quality castings.

- Premises

- Pattern shop

- Core shop

- Melting

- Fettling

- Quality Lab

Premises

Foundry Premises

Machine Shop Premises

Machine Shop Premises

- Total Land Area: 30,000 Sq Meters

- Foundry Office Area: 1000 Sq Meters

- Foundry Work Area: 15000 Sq Meters

- Machine Shop Office Area: 1000 Sq Meters

- Machine Shop Work Area: 3000 Sq meters

- A full fledged office with dedicated departments for Marketing, Sales , Finance & Accounts, Purchase, Production, Quality, and Logistics.

Pattern shop

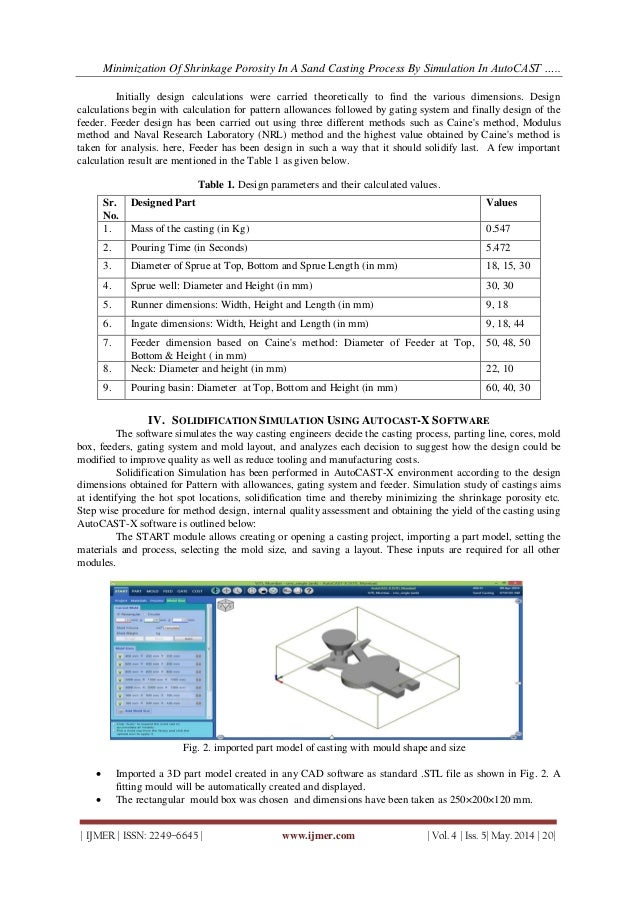

- Tooling Development is supported with CAD / CAM & AUTOCAST - Simulation Software facilities which minimizes the development time .

- We are capable of submitting all parts with APQP, FMEA, CONTROL PLAN, SPC,MSA,PSW,PPAP.

- In house facility for undertaking the Mounting of patterns followed by methoding and rework wherever required.

- Two numbers of Lathes, one Milling machine, one Cutting machine, Surface table, Height gauge, and Digital Vernier exclusively for handling pattern shop activities

- Coordinate Measuring Machine (CMM ) to inspect the First sample dimensions whenever required

Core shop

- A Shell Core Shooter of 5Kg capacity

- 3 Nos of Cold Box Core Shooter of 5Kgs, 10Kgs and 15 Kgs capacity

- Co2 Core making facility with 8 tables

- Heating Oven for baking of cores

- 2 nos x 250kgs Core Sand Mixer

- 2 Ton/hour capacity Core Sand Drier

Melting

- 2 Nos of Medium Frequency Induction Furnace with 600 KW capacity each of Inductotherm make

- Each of the above furnace has 2 Nos of 1 Ton Crucible

- 3 Ton EOT Crane with 250Kgs and 500Kgs Treatment ladles

- Mono Rail system for Pouring

- 4 Nos of 500 Kgs Ladles for magnesium treatment for Ductile Iron

- 12 numbers of SOHGS Hand Shanks.

- Dust collector facility for environmental protection

Fettling

- Hydraulic wedge cutting machine for breaking runner and riser

- Two numbers of 500 Kgs capacity shot blasting machine.

- 8 numbers of Bench grinders and 2 Nos of Swing frame grinders supported by combination of pneumatic grinders.

- Trimming Machine of 60 Tons capacity

- Tumble blasting machine of 300 Kg Capacity for cleaning of components

- Nozzle Blasting machine to clean intricate and complex core holes

Autocast Simulation software, free download Pc

Testing facilities

Autocast Simulation software, free download Windows 10

- Spectrometer: ARL (Swiss) make 29 element analyzer

- Image Analyzer with Camera Attached to Microscope

- Sand Testing Equipments

- Tensile & Hardness Tester

- CEE Meter

- Charpy impact tester